Efficiency and safety play a crucial role in industrial production processes. NitroNext is an IoT solution developed...

Nitronext helps production teams act before failures occur by wirelessly monitoring gas spring pressure, instantly alerting maintenance teams in case of pressure loss, preventing potential downtime and quality defects.

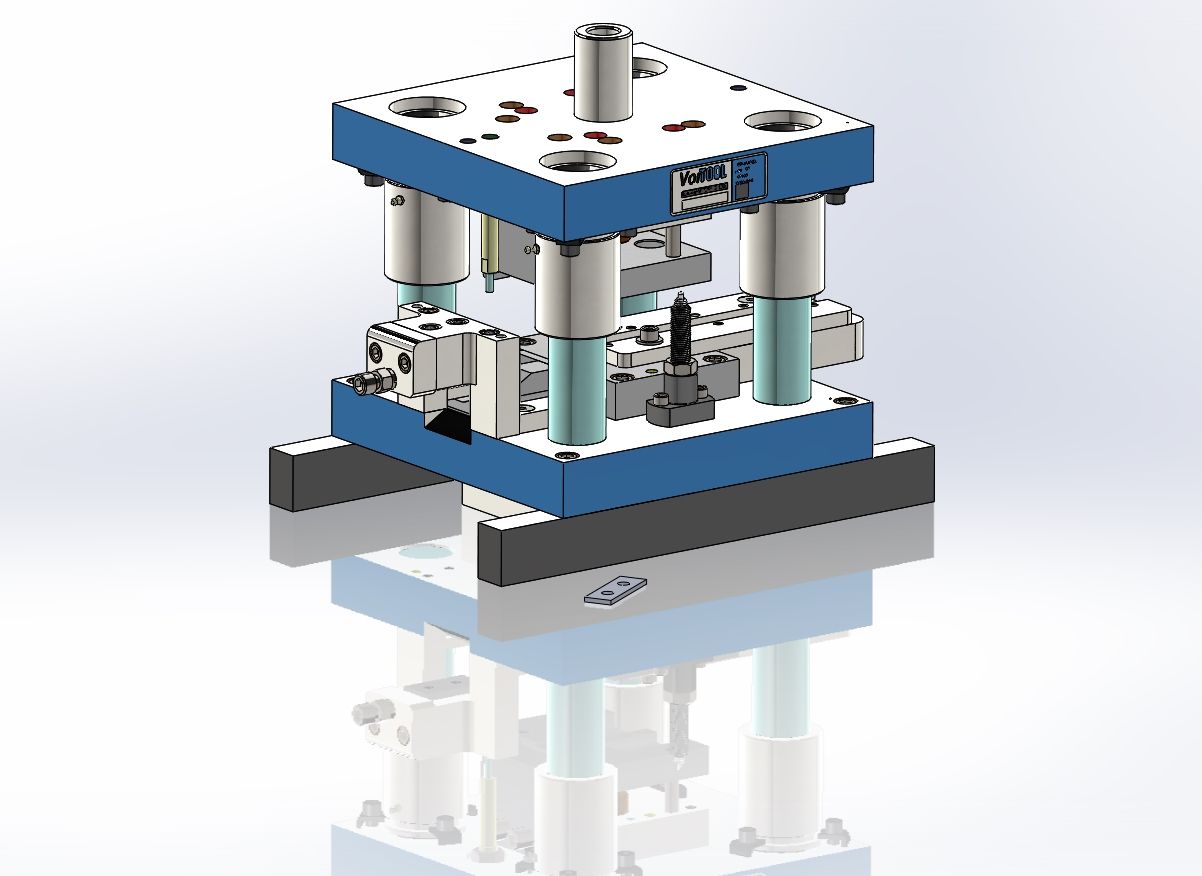

Nitronext simplifies pressure monitoring across your factory. It wirelessly tracks gas springs and other pressure-based components, delivering real-time data and alerts. The system can be installed without interrupting production and activates instantly. When the die connects to the press, it charges automatically and gets ready for the next cycle.

Thanks to the developed notification system, necessary notifications are instantly sent to predefined users via email.

With wireless communication and low power consumption, sensors operate energy efficiently. The system allows sensors to transmit data from long distances.

With the user interface, the status of the dies can be monitored in real-time, and pressure changes in the dies can be tracked historically through reporting screens.

When the die is connected to the press, the batteries charge automatically. The device is designed according to the press's requirements and is resistant to vibration.

Nitronext instantly detects hard-to-see problems on your production line and allows you eliminate them before they turn into costly issues.

Identify potential problems before they occur for uninterrupted and smooth production.

Prevent quality issues caused by low pressure right from the start.

Minimize the need for manual checks and reduce occupational safety risks on the press line.

Monitor the pressure of each gas spring in real time. Keep your production line under full control at all times.

Receive instant SMS and email notifications for pressure drops below your defined threshold.

Detect pressure-related issues early and build your maintenance plan based on data.

Identify pressure loss in gas springs before it leads to problems. Nitronext keeps your production running without interruption.

Nitronext works without requiring complex installations or software. You can start using it immediately without stopping your production line.

Sensors integrated into gas springs are easily mounted. No need to stop the line.

Gas spring pressure is measured every 10 minutes and wirelessly sent to the receiver.

Die status can be monitored in real time via mobile, interface, and on-site andon screens.

When pressure drops below your threshold, SMS / Email notifications are sent.

Check Our Frequently Asked Questions Section For What You Are Curious About

"We used to discover gas spring leakages too late, usually after they had already caused production downtime. Since implementing Nitronext, we can detect leaks early and prevent costly downtime. It's now a critical tool for keeping our lines running efficiently."

Our Latest Articles

Efficiency and safety play a crucial role in industrial production processes. NitroNext is an IoT solution developed...

Sheet metal forming using press machines is a widely employed manufacturing method in industries such as automotive,...

In modern manufacturing processes, press machines and sheet metal forming technologies play a critical role. The gas...

With the development of Industry 4.0, manufacturing processes have become smarter and more efficient. In this...

Ulutek Teknoloji Geliştirme Bölgesi Bursa Uludağ Üniversitesi

Üniversite 1. Cad. No: 933 / Z013

Nilüfer Bursa Türkiye